A number of design methodologies have been proposed for GRPE's BS 8006 : 1995, EBGEO, Carlsson, Hewlett and Randolph, Russell et al.

In both design and analysis of geosynthetic reinforced piled embankments analytical and numerical techniques are utilized.

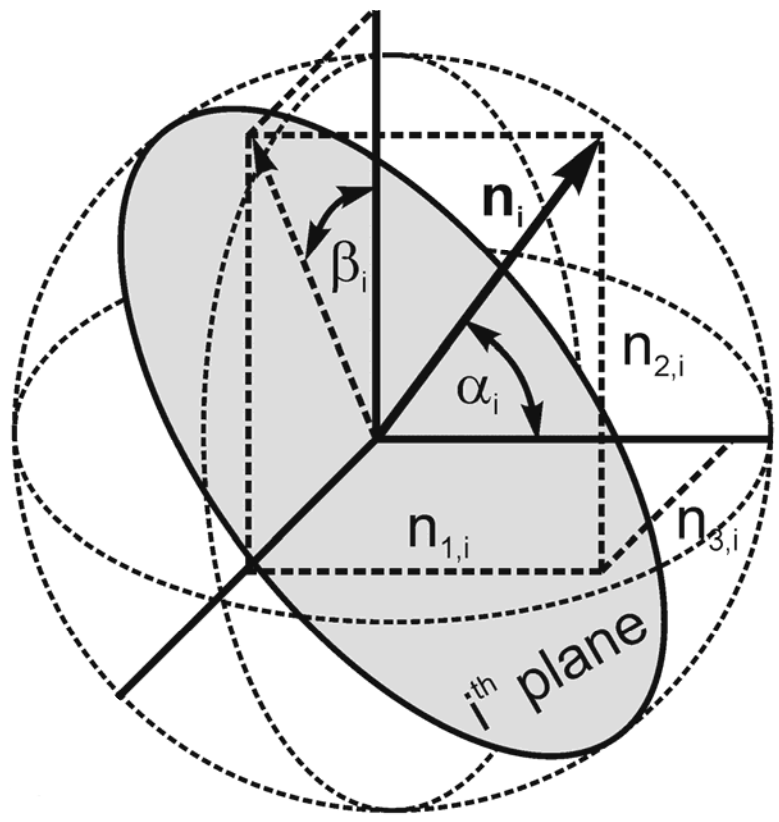

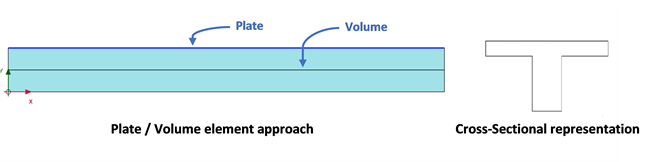

The design of reinforced piled embankments is a complex soil-structure interaction problem involving embankment fill, geosynthetic reinforcement, a pile group, and the soft underlying soil see Love and Milligan. Typical geosynthetic reinforced piled embankment. Rowe and Li, Bergado and Teerawattanasuk Briançon and Villard Li and Rowe Rowe and Taechakumthorn Abusharar et al. The inclusion of geosynthetic reinforcement just above the pile caps enhances the load transfer efficiency, minimizes yielding of the soil, and reduces total and differential settlements, Han and Gabr Russell and Pierpoint Varuso et al. Pile/column supported embankments improve structural stability and reduce embankment deformations. Han and Gabr suggested the benefits associated with reinforced piled embankments are (1) single stage construction without prolonged waiting times (2) significantly reduced differential settlements (3) reduced earth pressures (4) to avoid excavation and refill employed. The geosynthetic-reinforced piled embankment (GRPE) structure consists of closely spaced piles which penetrate the soft soil to reach a stiff bearing substratum, the pile group is overlain by the geosynthetic reinforced, upon which the embankment is constructed, Figure 1. Geosynthetic reinforced piled embankments are widely used to overcome these problems when constructing on soft soil. Design of embankments on soft ground raises several concerns such as bearing capacity failure, differential settlements, lateral stresses, and structural instability. Special construction methods are required when embankments are constructed on very soft clay or peat.

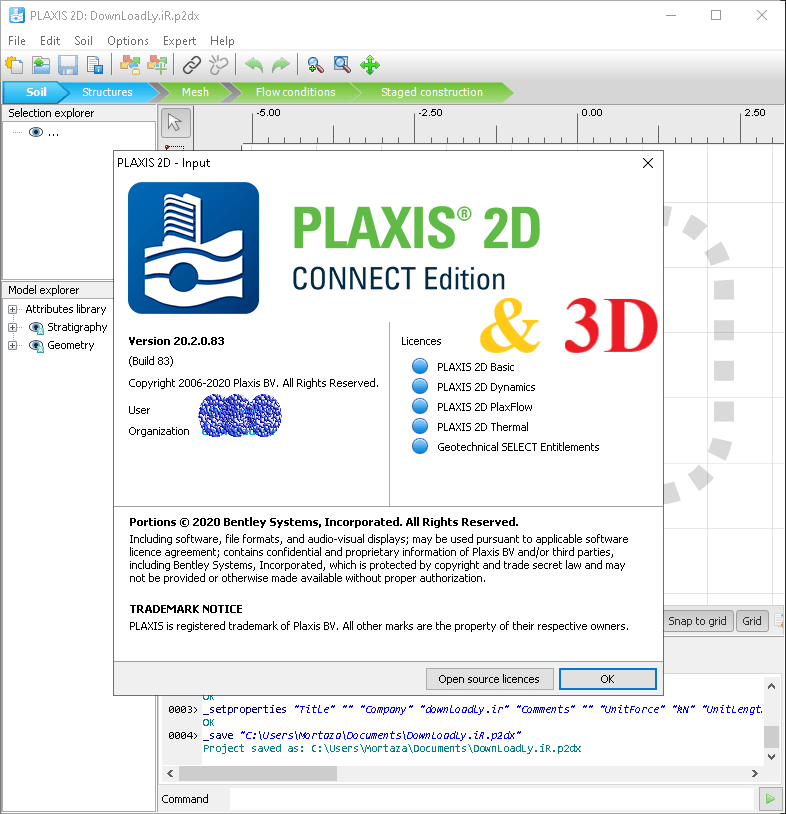

However the FDM approach was found to give a slightly higher reinforcement tension and stress concentration but lower reinforcement strain at the pile cap than FEM, which was attributed to the greater discretize of the model geometry in the FDM than in FEM. FEM consistently replicated the FDM outputs for deformational, loading, and load transfer mechanism (soil arching) response within the reinforced piled embankment structure with a reasonable degree of accuracy. The FEM and FED techniques were found to be in reasonable agreement, in both characteristic trend and absolute value. Plaxis 2D (FEM) was utilized to replicate FLAC (FDM) analysis originally presented by Han and Gabr on a unit cell axisymmetric model within a geosynthetic reinforced piled embankment (GRPE). The numerical modelling of geosynthetic-reinforced piled embankments using both the finite element method (FEM) and finite difference method (FDM) are compared.

0 kommentar(er)

0 kommentar(er)